From sketch to service

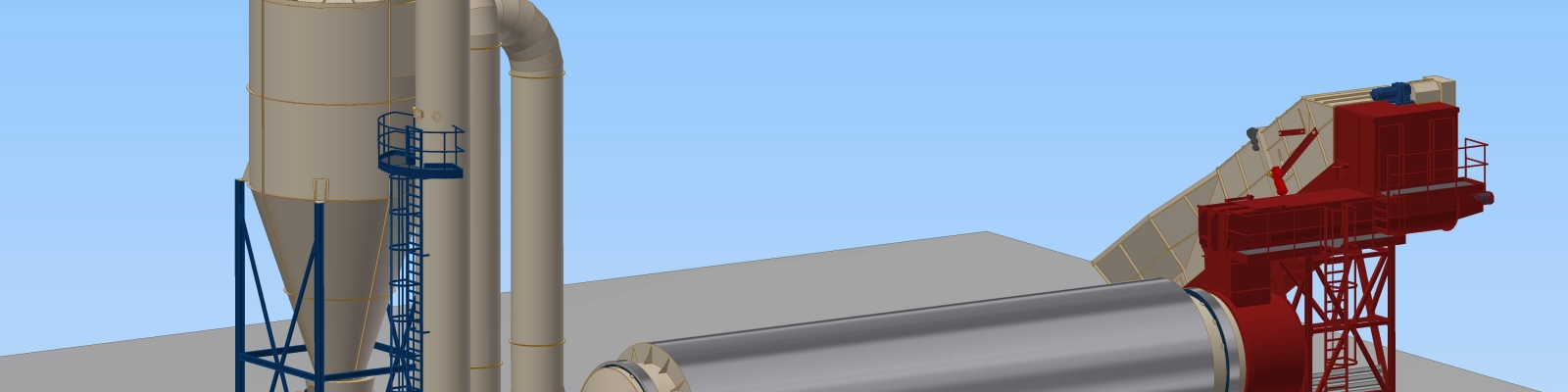

Every Dutch Dryers thermal drying system is custom made and configured to your specific requirements.

- Orientation. The drying of residual flows can involve innovation. You may be wondering whether your ideas are feasible and whether the drying of specific materials is possible. In this phase we are happy to work with you as a sparring partner.

- Design. We elaborate on a design for a thermal drying system. Our engineers calculate the required capacities, specifications, yields and dimensions. Furthermore, on the basis of the design, we are also able to define the expected investment.

- Pilot. If your project involves a new application we can potentially run a pilot project for which we build a test system at the required scale. On the basis of the pilot we are able to optimise the (process) design.

- Build and installation. We build the complete system as per the design. The components are assembled on your site in order to create an operational thermal drying system.

- Commissioning. Our engineers undertake the commissioning of your system. We remain involved from the start of production and we optimise the system until the outlet meets your requirements.

- Service and maintenance. We are always ready to assist, whether it’s to resolve a fault or implement a modification. Many service tasks can be performed remotely by logging in to the systems’ control environment.

Spain

The production of wood pellets from sawdust

Wood fibres and sawdust are a source of energy, provided that they ...

Read moreBecome an agent

Do you want to explore a partnership with Dutch Dryers. Don't hesitate to contact us and become our next agent.